Purpose

In a world increasingly dependent on manufactured technology, OEMs (Original Equipment Manufacturers), ODMs (Original Design Manufacturers), and EMS (Electronics Manufacturing Services) providers play vital roles behind the scenes. This article aims to clarify these terms, how they differ, and why they hold strategic value in modern supply chains.

What is an OEM?

OEM stands for Original Equipment Manufacturer. This refers to a company that produces components or products that are purchased by another company and retailed under that purchasing company’s brand name.

- Example: Foxconn manufactures Apple’s iPhones — Foxconn is the OEM, Apple is the brand.

What is an ODM?

ODM stands for Original Design Manufacturer. An ODM designs and manufactures a product that is then sold by another company under their own brand. This model is common in consumer electronics and personal care appliances.

- Example: A retailer buys pre-designed wireless earbuds from an ODM, adds its logo, and sells them as its own brand.

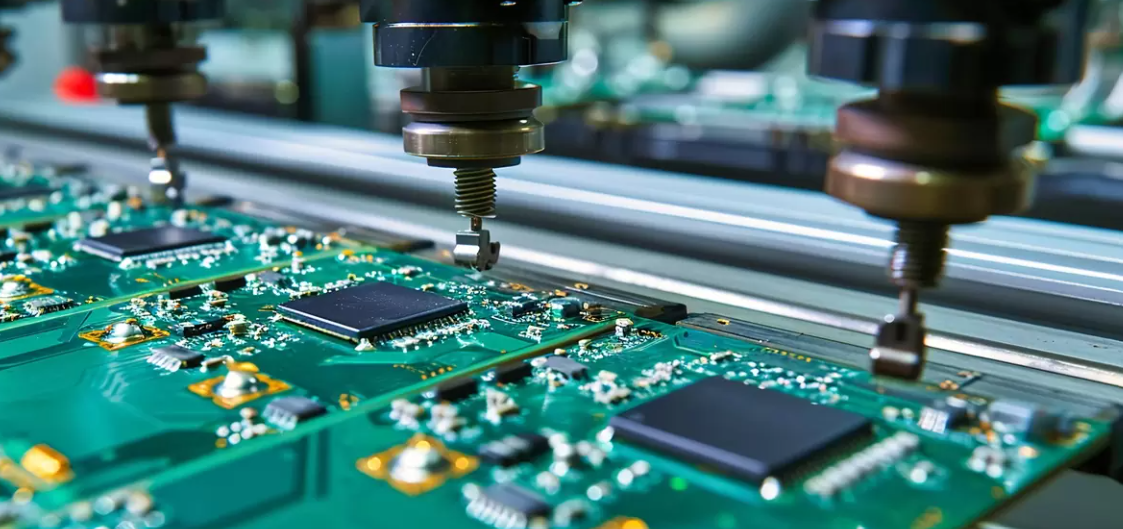

What is an EMS Provider?

EMS stands for Electronics Manufacturing Services. EMS companies assemble, test, and sometimes design electronic components or products. They often serve OEMs by handling tasks like PCB assembly, box builds, and logistics.

- Example: Jabil and Flex are EMS companies that manufacture and assemble products for brands like Cisco and HP.

OEM vs ODM vs EMS: A Comparison

| Aspect | OEM | ODM | EMS |

|---|---|---|---|

| Design ownership | Client | Manufacturer | Client |

| Manufacturing | Yes | Yes | Yes |

| Product customization | High | Low to Medium | High (assembly level) |

| Typical Use Case | Proprietary designs | White-label products | Electronic device manufacturing |

Benefits of OEM Relationships

Engaging with OEMs can offer many operational and strategic advantages:

- Lower manufacturing costs due to economies of scale

- Faster time-to-market by leveraging experienced manufacturers

- Focus on branding, marketing, and customer experience

- Access to specialized manufacturing capabilities

--- Real-World Use Cases ---

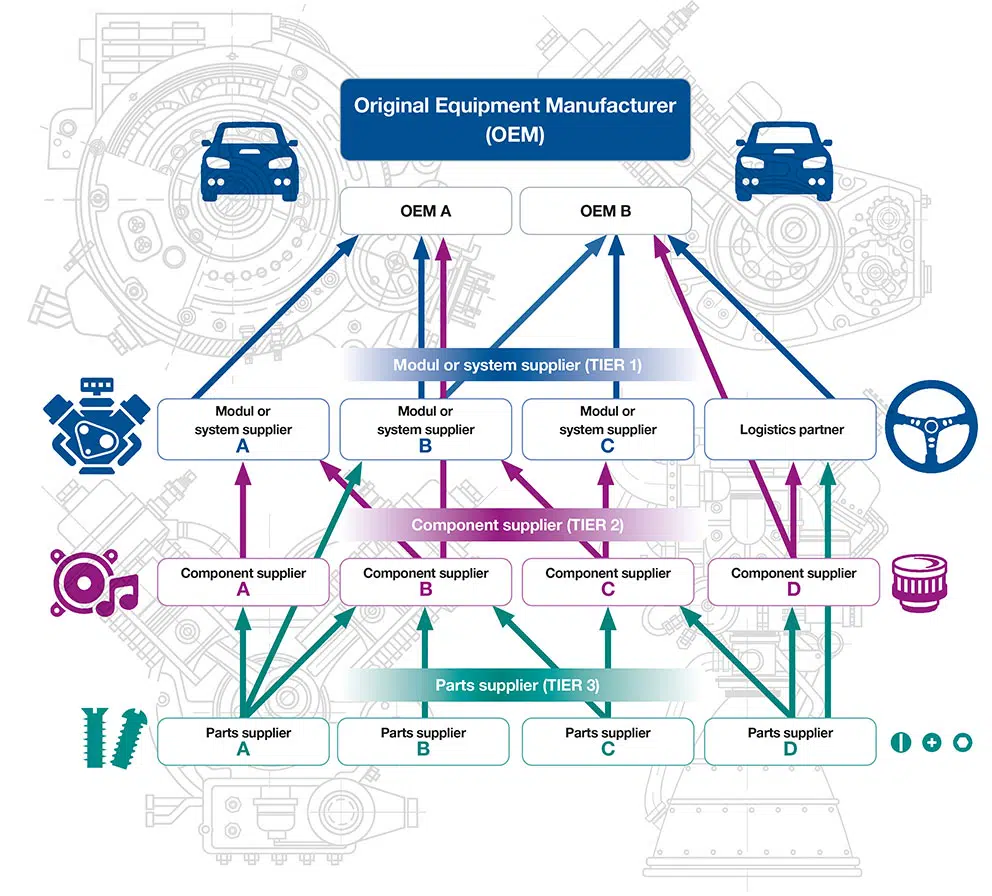

Automotive Industry (OEM)

OEMs supply key components like braking systems, sensors, or entire engine assemblies to car manufacturers.

Consumer Electronics (ODM)

ODMs allow fast product rollouts with minimal R&D by providing ready-to-brand electronic products.

Printed Circuit Board Assembly (EMS)

EMS providers handle complex circuit assembly, testing, and shipping for large OEMs and ODMs alike.

--- Industry Challenges ---

Each model has unique risks:

- OEMs: Risk of dependency on supplier quality and stability

- ODMs: Less differentiation due to shared product designs

- EMS: Complex supply chains and margin pressure

Supply Chain Complexity

Trends in Manufacturing Models

The OEM/ODM/EMS landscape is being shaped by:

- Smart manufacturing and IoT integration

- Nearshoring to reduce risk and lead time

- Sustainability and regulatory pressures

- Cloud-based supply chain collaboration tools

Conclusion

OEMs, ODMs, and EMS providers are foundational to product development in nearly every industry. Understanding their roles allows businesses to build agile, scalable, and cost-efficient supply chains.

- OEMs provide scalability and production expertise based on client designs.

- ODMs enable fast go-to-market with ready-made solutions.

- EMS providers support electronic manufacturing with advanced assembly and logistics services.

Choosing the right model depends on your company's design control, differentiation needs, and technical resources.